Femtosecond/Picosecond DUV Laser

Ultrafast Deep Ultraviolet 266nm Laser Micro-etching, Micro-drilling, and Micro-cutting

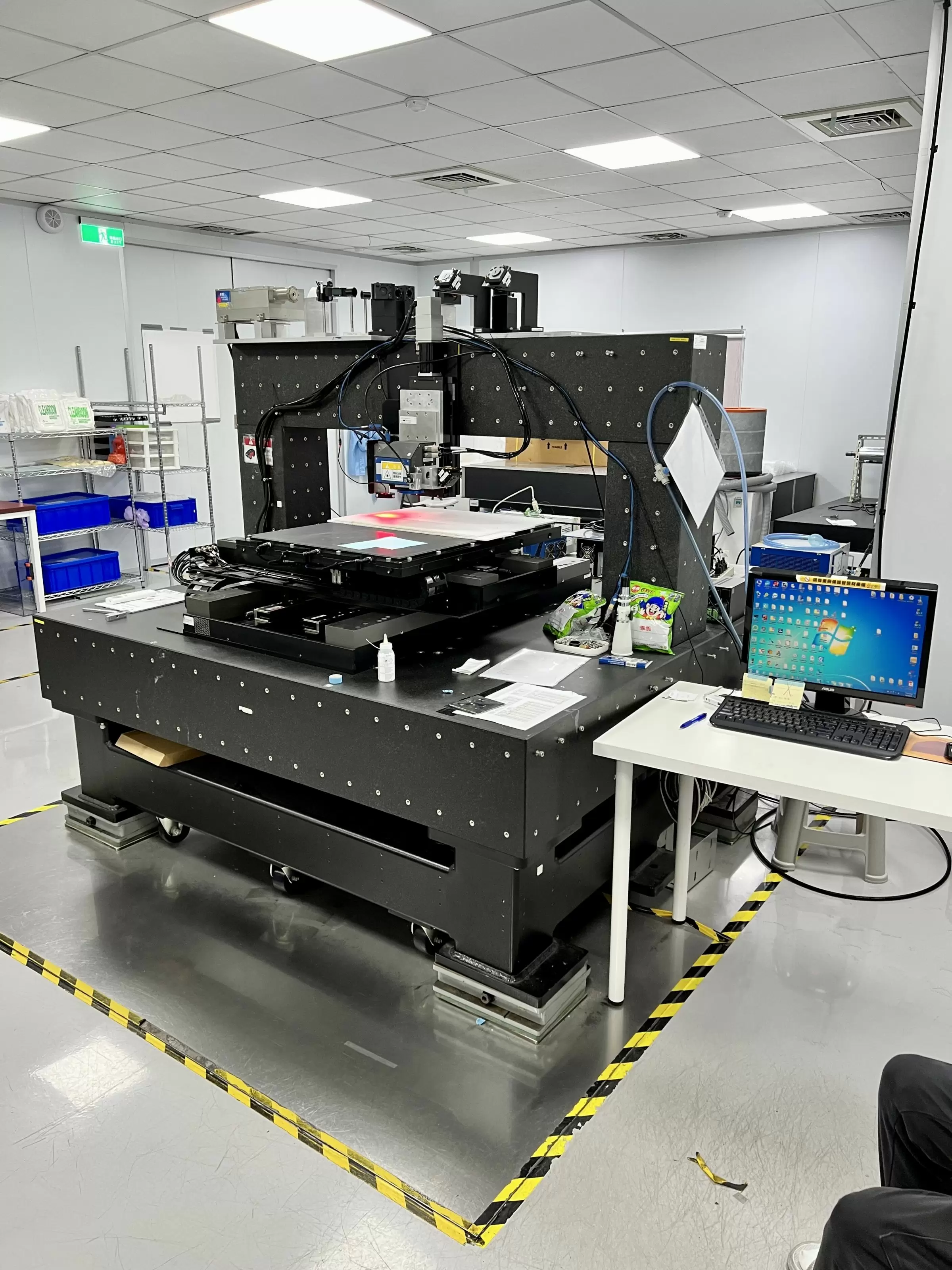

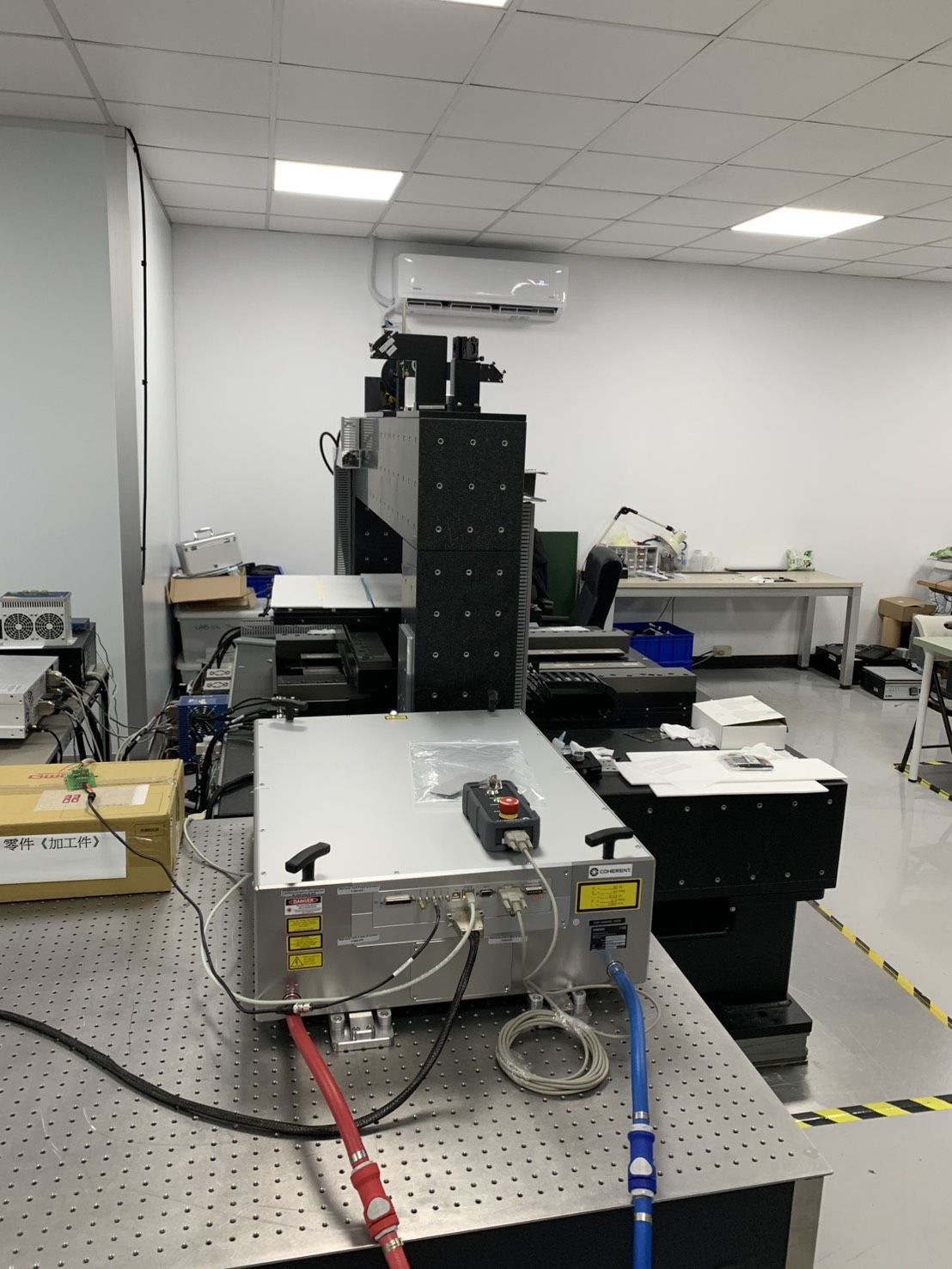

Hortech has developed the ultra-fast DUV cold laser machine with large power that performs etching, drilling, and cutting in our lab. It can implement different processes on diverse materials, including: lift-off, semi-cut, laser grooving, plasma vertical cutting, etc. You may make a reservation with Hortech. We can schedule and arrange for you.

Hortech develops the ultrafast DUV laser machine with short pulse at micron precision. The effective motion processing area is 500x500 mm and the automatic machine platform is 650x850 mm. It can perform ultra-precision, heterotypic processing and finishing on 2D curved surfaces with equivalent energy at the same location. You may contact us to make a reservation. We provide both short-term and long-term leasing and OEM processing services. Discounts are offered to members of the Taiwan Allied Association for Science Park to shorten the supply chain. The scope of the technical service includes: (1) 18” wafer backend packaging processes; (2) Cold laser processing and finishing processes; (3) Laser micro-drilling and micro-cutting on polymer/composite materials; (4) Laser micro-drilling and micro-cutting on functional sheet metal; (5) Laser micro-etched circuits: Circuit patterning on thin films that are composed of multilayered materials; (6) Micro-LED wafer laser lift-off; (7) Photoresist (PR) patterning on silicon (Si) wafer (< 18”) by plasma dicing; and (8) Laser micro-holes drilling (< 20 um) on ABF/BT/Si.

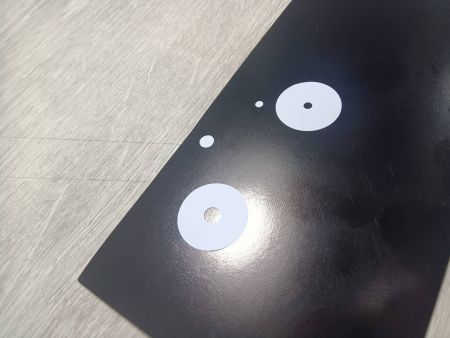

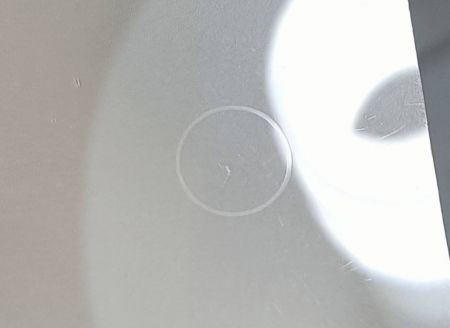

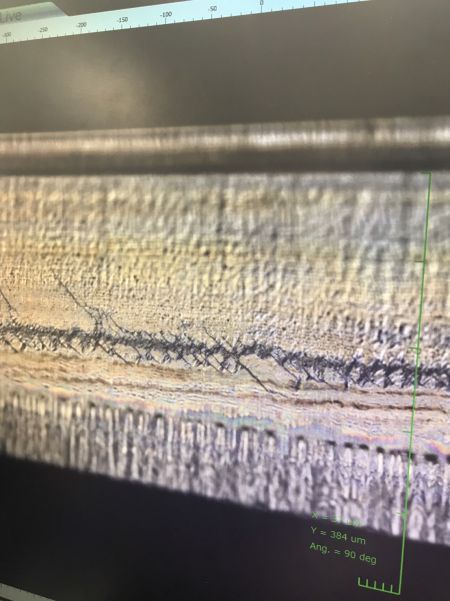

Laser micro-cut & micro-drilled thin films

Thin films encompass metal materials and organic materials. Their thickness is between monoatom/single...

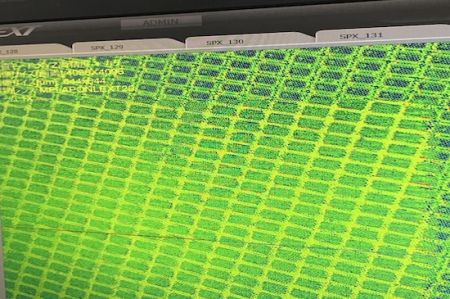

DetailsFemtosecond/Picosecond DUV Laser with Large Power - Laser micro-etched circuits on polycarbonate thin films

Hortech has successfully employed the DUV laser to produce circuits on polycarbonate thin films....

DetailsFemtosecond/PicosecondDUV Laser with Large Power - MicoLED Lift-off

The laser can be employed to fabricate microLEDs. This includes: (1) transfer and mount on sapphire...

DetailsFemtosecond/Picosecond DUV Laser with Large Power - Semicut Polymer

Semi-cutting films is often required when it comes to processing multi-layered materials. Performing...

DetailsFemtosecond/Picosecond DUV Laser with Large Power - Cutting Multi-layered Composites

Hortech exploits how different materials absorb the DUV laser to cut gradually until reaching...

DetailsFemtosecond/Picosecond DUV Laser with Large Power - Thin Wafer-dicing

The laser with DUV wavelength can gasify and lift off the material by extremely high photon...

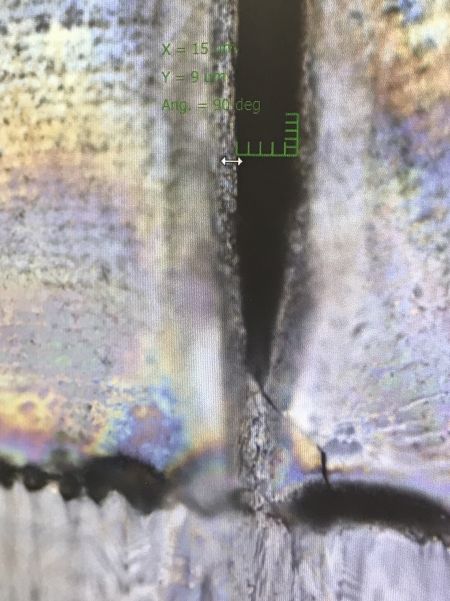

DetailsFemtosecond/Picosecond DUV Laser with Large Power - Laser Grooving and Plasma Vertical Cutting Through Sicilon Wafer

Employing conventional processes to dice thick silicon wafers, including direct laser cutting...

DetailsFemtosecond/Picosecond DUV Laser | Laser Processing Services & Custom Designed Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Femtosecond/Picosecond DUV Laser, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.