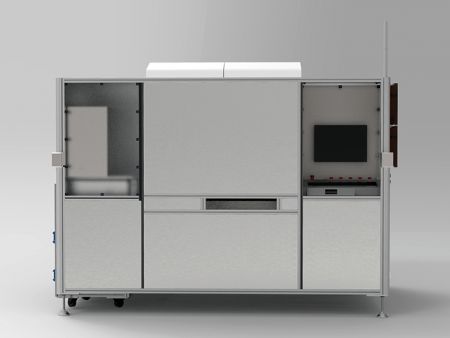

Laser Micro-etching System for Thick Films

Etching on films having micron thicknesses, micro-etching on functional materials

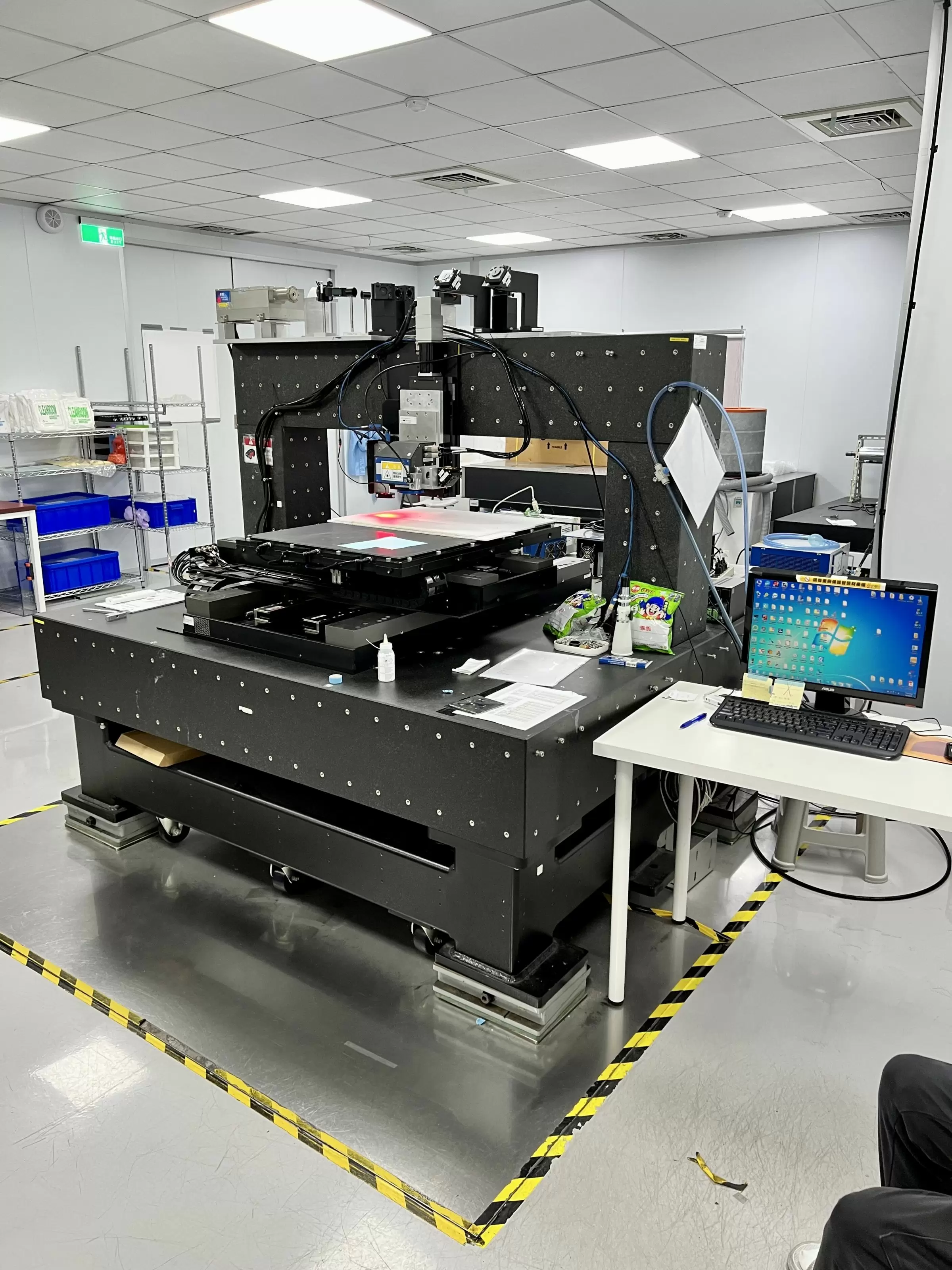

The dust generated during the process of laser micro-etching on thick films tends to cause defection. In this way, the precision laser finishing process will not be able to achieve acceptable or high yield rates. This patented laser system solves the above problem by finishing the surface of products that are hung upside-down. The dust falls off without damaging the surface. Vacuum cleaning is employed at the bottom simultaneously. Subsequent cleaning is not required. This laser micro-etching system can be installed for pattern production on substrates made of thick films.

Precision Laser System for Highly Efficient Mass Micro-Etching

Hortech integrates the high-precision, upside-down motion control module with the optical focus system to develop this laser system. Precision laser finishing is employed when it undertakes the upside-down motion control. The dust generated in the process falls off due to the gravity, which is removed by the negative pressure. The above process enables highly stable mass production as well as achieves high yield rates.

Laser micro-etching system with effective dust removal finishing mode

- Dust removal by the upside-down gravity.

- Vacuum cleaning from top to bottom.

- Laser with optical focus.

- Dust prevention by positive pressure.

Circuit Patterning on Micron Thick Films

- The linewidth of the laser micro-etching is smaller than 20um on films at 4 - 12um.

- The collimation degree of the laser line < +/- 2um.

- The turning R angle of the laser is <20um according to the client's request.

- The positioning accuracy of the laser is < +/- 5um at 500 x 500mm.

- The required laser sources include: 1030-1070, 515-532, 343-355, 257-258nm.

Laser Micro-etching System for Thick Films | Laser Engraving & Micro Cutting Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Laser Micro-etching System for Thick Films, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.